|

Follow us |

||

|

|

|

|

|

|

|

|

|||||||

|

WorkNC Dental

reflects Vero Software's 20 years experience and expertise in the field of CAD/CAM. |

||

|

The

|

|

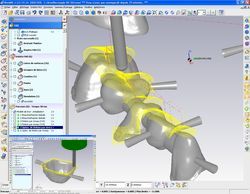

| WorkNC Dental comprises a comprehensive range of automated and interactive procedures that will help the user throughout the part machining preparation process - the choice of the machining blank, the addition of support pins and finally the launching the machining process itself. | ||

Steps of DENTAL CAD/CAM Process The process starts with an impression scanned by a non-contact 3D laser scanner. The scan data is then used to generate a digital model from the impression with the CAD software. The virtual CAD model is then used to generate the desired prosthesis design. Next both the completed design and the digital model are ready for programming in WorkNC Dental automatic CAM software. The process is completed by machining both the completed restorations and their model in 4- or 5-axis on laboratory CNC milling machines. |