|

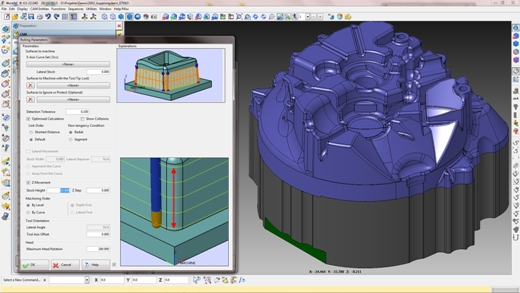

The new WorkNC Dental V4 will feature on WorkNC’s

booth – F22 in hall 8. This latest version of the dental

solution provides a wide range of innovative automatic machining

functions for dental prosthesis, whatever the process. It includes new

automatic cavity recognition for fully automatic machining on both 3 +

2 and 5-axis machines, through the faultless detection of concurrent

or diverging insertion axes. This new functionality provides optimal

use of 3+2 machines which do not have simultaneous 5-axis

capabilities.

Another step forward in its automatic machining processes: machine

characteristics and kinematics are now taken into account before

calculations are run. This means users are immediately aware of

any feasibility issues, managing project preparation in real time.

And visitors to the exhibition can see the software in action on

the Datron booth (D68, hall 8), which will include machining

Chrome Cobalt and Titanium dental implants using WorkNC Dental on a D5

dental CNC 5-axis mill.

In addition, WorkNC V22, WorkXPlore 3D V3,WorkPLAN SolutionsV3 will

all be on show at the exhibition, which is being held at Frankfurt in

Germany, from December 3 to 6. |