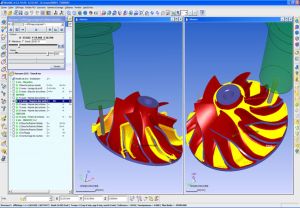

WorkNC 3X provides engineers with a core range of the

two- and three-axis automated tool paths previously only available in the

full version of WorkNC. These include automatic three-axis roughing and

finishing, contour and pencil machining and automated drilling.

WorkNC 3X toolpaths have intelligence built in,

generating smooth transitions and fluid cutterpaths suitable for high-speed

machining and cutting complex geometry.

Furthermore, the system can learn from and store an

individual company's machining methods, adding to its expertise and reducing

reliance on human knowledge.

For toolmakers and manufacturers, this makes the

software easy to use on the shop floor and introduces reliable and

high-quality machining methods quickly.

Companies can cut their production times and improve

part quality without introducing unnecessary complexity.

These enable model and drawing data to be easily

imported, allowing smaller companies to compete for a wider range of

business with confidence.

Specialist application CAD capabilities inside

WorkNC 3X allow users to manipulate designs ready for machining, speeding up

and simplifying program preparation.

WorkNC 3X offers reliability and the features

WorkNC's collision detection and avoidance module as standard.

For smaller machinists and toolmakers, WorkNC 3X

will provide a fast and cost-effective way of transforming their machining

capabilities, with rapid return on investment delivered by shorter

deployment times, improved quality and simple operation.

Users can start producing 3D parts right away, and

will be operating at expert level, cutting complex parts and moulds after

one or two days' training. |